Stainless Steel Labels

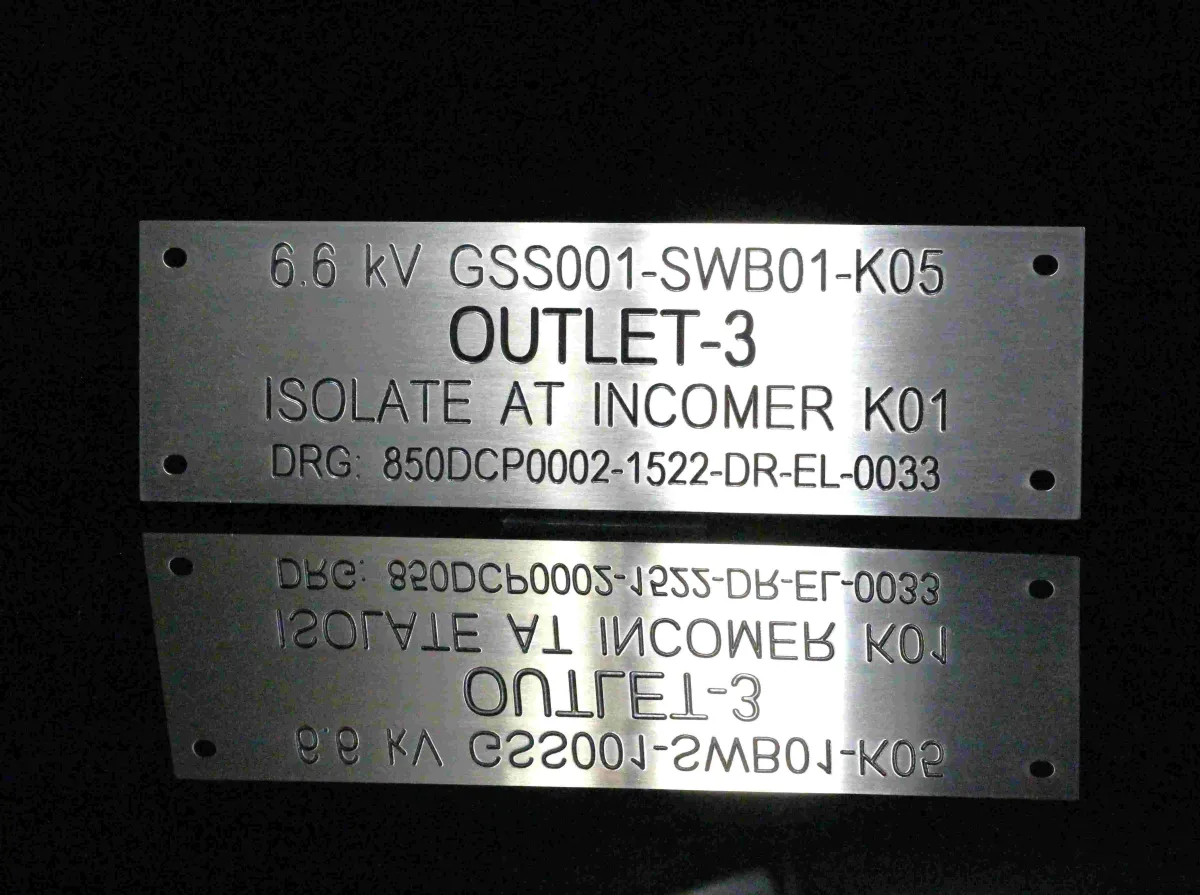

Stainless steel labels are renowned for their resilience and versatility. They are ideal for industries such as mining, construction, manufacturing, and engineering due to their ability to resist corrosion, extreme temperatures, and wear. These labels are perfect for environments where durability is non-negotiable.

We craft durable, precise, and visually appealing stainless steel labels for industrial equipment, electrical panels, and custom signage. Built to withstand harsh environments while maintaining a polished look, our labels meet the highest standards with advanced engraving technology and unmatched craftsmanship.

Stainless Steel Labels

Stainless steel labels are renowned for their resilience and versatility. They are ideal for industries such as mining, construction, manufacturing, and engineering due to their ability to resist corrosion, extreme temperatures, and wear. These labels are perfect for environments where durability is non-negotiable.

We craft durable, precise, and visually appealing stainless steel labels for industrial equipment, electrical panels, and custom signage. Built to withstand harsh environments while maintaining a polished look, our labels meet the highest standards with advanced engraving technology and unmatched craftsmanship.

Production Excellence

By leveraging advanced, purpose built technologies and streamlined methods, we have elevated the automation of label production to new heights within the engraving sector. This ensures superior precision, reduces errors, and maintains consistent quality across all outputs.

Our in-house fibre laser cutter empowers us to craft custom stainless steel profiles efficiently, eliminating delays associated with external sourcing.

Laser Cutting

Using our advanced in-house fibre laser cutter, we can precisely cut materials up to 3mm thick. This provides great design flexibility and fast turnaround times, eliminating delays from external suppliers while ensuring accurate, high-quality results.

Premium Materials

We exclusively use 316-grade stainless steel for our labels, renowned for its exceptional corrosion resistance and durability. This premium material ensures that our labels perform well in harsh environments, making them ideal for industrial applications.

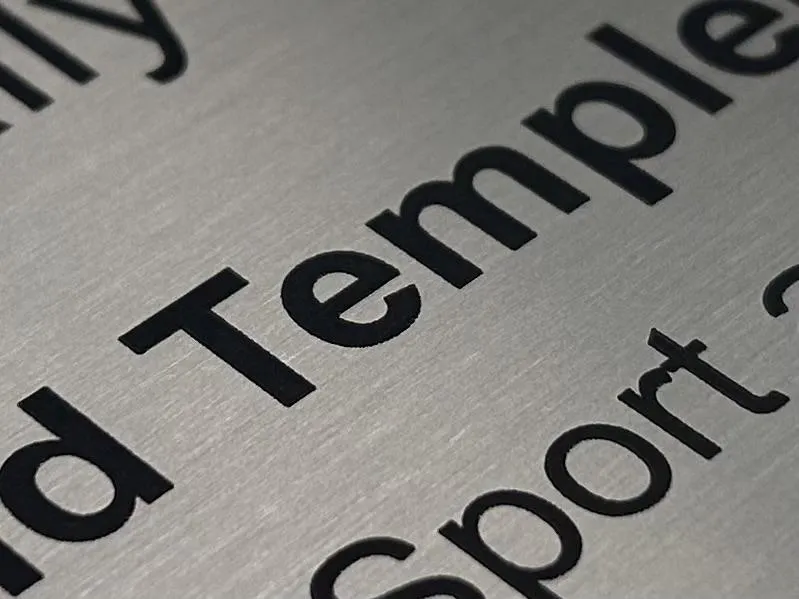

Each label features a brushed finish, providing a sleek and professional aesthetic that enhances the visual impact while reducing glare.

Our stainless steel labels are available in thicknesses of 0.9mm, 1.2mm, 1.5mm, and 2.0mm.

Durable Laser Etching

Our etched stainless steel labels are precision sub-surface etched using our advanced fibre laser engraver. This process ensures that the information etched onto each label remains legible and intact over time, withstanding even the most demanding environments.

Robust CNC Engraving

Our stainless steel labels are meticulously engraved using advanced CNC machining with precision carbide cutters. This method ensures clean, accurate engravings that stand up to wear and tear. For added durability and a polished finish, we offer paint filling using powder coat technology, providing exceptional resistance to fading and UV exposure for long-lasting performance in even the harshest conditions.

Production Excellence

By leveraging advanced, purpose built technologies and streamlined methods, we have elevated the automation of label production to new heights within the engraving sector. This ensures superior precision, reduces errors, and maintains consistent quality across all outputs.

Our in-house fibre laser cutter empowers us to craft custom stainless steel profiles efficiently, eliminating delays associated with external sourcing.

Laser Cutting

Using our advanced in-house fibre laser cutter, we can precisely cut materials up to 3mm thick. This provides great design flexibility and fast turnaround times, eliminating delays from external suppliers while ensuring accurate, high-quality results.

Premium Materials

We exclusively use 316-grade stainless steel for our labels, renowned for its exceptional corrosion resistance and durability. This premium material ensures that our labels perform well in harsh environments, making them ideal for industrial applications.

Each label features a brushed finish, providing a sleek and professional aesthetic that enhances the visual impact while reducing glare.

Our stainless steel labels are available in thicknesses of 0.9mm, 1.2mm, 1.5mm, and 2.0mm.

Durable Laser Etching

Our etched stainless steel labels are precision sub-surface etched using our advanced fibre laser engraver. This process ensures that the information etched onto each label remains legible and intact over time, withstanding even the most demanding environments.

Robust CNC Engraving

Our stainless steel labels are meticulously engraved using advanced CNC machining with precision carbide cutters. This method ensures clean, accurate engravings that stand up to wear and tear. For added durability and a polished finish, we offer paint filling using powder coat technology, providing exceptional resistance to fading and UV exposure for long-lasting performance in even the harshest conditions.